HF-GENERATOR FOR BONDING OF ACETATE COMPONENTS

Heater with high-frequency generator series LFA/I45 is a machine,

specially developed for bonding of plastic and acetate material by

using special glue (no aceton).

Technical Data:

| Power supply: | 400 V 50/60 cycles |

| Power consumption: | 4,5 KvA |

| Machine width: | 500 mm |

| Machine height: | 410 mm |

| Machine depth: | 1160 mm |

| Weight: | 85 kg |

"CE"-regulations are met

All data subject to change!

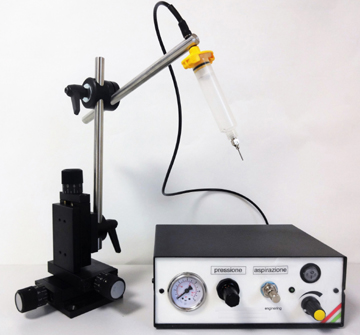

DOSING UNIT (GLUE) FOR HF-BONDING GENERATOR

Pneumatic dispenser for glue complete with micrometric adjustable support and pedal foot switch.

Suitable for all types of fluids

Vacuum suck-back will effectively control glue dripping or stringing.

Technical Data:

| Dispense time: | 0,1-20,00 seconds |

| Voltage: | 230V 50/60 Hz |

| Internal Voltage: | 24VDC |

| Air input: | 3 - 7 Bar |

| Air output: | 0,1 - 7 Bar |

| Weight: | 2,2 kg |

"CE"-regulations are met

All data subject to change!

Schüssler S-562 Programming station

Programming station with lens former tracing device and industrial type PC.

The following software packages are available:

- Software MAKE DXF - S-562

- Software S-50x - S-562 for S-500, S-501, S-503

- Software S-6x0 S-50x - S-562 for S-502, S-504, S-610, S-620

- Software S-63x - S-562 for S-633 and S-634

Technical Data:

| Power supply: | 230 V singlephase 50/60 cycles |

| Power consumption: | 0.2 kW - 4 A |

| Machine width: | 520 mm |

| Machine height: | 410 mm |

| Machine depth: | 440 mm |

| Weight: | 22 kg |

"CE"-regulations are met

All data subject to change!

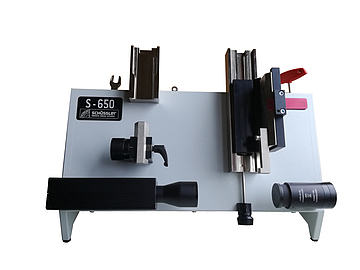

Schüssler S-650 cutter adjusting device

Cutter adjusting device for spindle type 5043 / 5046

This device must be connected to a PC via USB

Technical Data:

| Power supply: | 230 V singlephase 50/60 cycles |

| Electric specifications: | 5 VDC - 200 mW |

| Machine width: | 520 mm |

| Machine height: | 380 mm |

| Machine depth: | 320 mm |

| Weight: | 16,5 kg |

"CE"-regulations are met

All data subject to change!

Schüssler S-70 - Manual thread cutter

Thread-cutting, primary and secondary Simple, space saving design, vertical or horizontal installation possible Simplicity operation, both hands free.

Technical data:

| Power supply: | 220 V single phase 50 Hz 50 Watt |

| Chuck: | 0 - 3 mm |

| Net weight: | 3,5 kg |

| Machine width: | 180 mm |

| Machine height: | 90 mm |

| Machine depth: | 130 mm |

No maintenance

"CE"-regulations are met

All data subject to change!

Schüssler S-875 - Electronic screwdriver with torque

Since a couple of years our sales programm covers the Electronic Screwdriver S-875 with interchangeable heads S-880, S-881 and S-882. This reliable and handy little machine is nowadays frequently used in the assembly of fashionable masks and sports glasses.

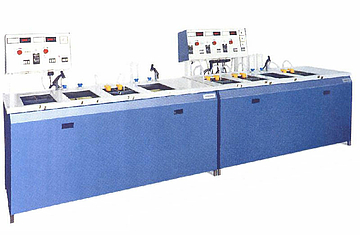

Download Info-PDF MoreElectroplating installations

for

- Ultrasonic Cleaning

- Electrolytic Degreasing

- Copper plating

- Nickel plating

- Gold plating (micron)

- Colour Gilding

- Rhodium plating

- Drying

The installations are built in a modular design. Thanks to a clear technical configuration and easy access for maintenance, this system guarantees trouble-free and economic electroplating.

We shall be glad to assist you in selecting the most suitable bath sequence for your particular requirements.

"CE"-regulations are met

All data subject to change!

Schüssler S-5039

Testing and Run-in Device

for SCHÜSSLER Milling Spindles of CNC Machines:

- S-610

- S-611

- S-620

- S-633

- S-634

- S-635

- S-636

- S-637

- S-5010

- S-5013

- S-5200

- S-5201

- S-5400

"CE"-regulations are met

All data subject to change!

Schüssler S-915 - Precision saw

for "V" cutting of rim-locks soldered to eye-rims.

The self-centering clamping fixture adjusts automatically to any rim-lock diameter. The entire fixture can be moved laterally so as to determine the exact position of the "V".

The angle of the "V" is fixed to 120 degrees.

Technical data:

| Spindle motors: | 230/400 V threephase / 50 - 60 Hz, 0,25 kW each |

| Spindle speed: | 1300 rpm |

| Spindle shaft: | diameter 16 mm, for saw blades 63 x 16 mm |

| Output: | approx. 500 cuts/hour |

| Machine width: | 600 mm |

| Machine height: | 400 mm |

| Machine depth: | 600 mm |

| Net weight: | 65 kg |

"CE"-regulations are met

All data subject to change!

PadPrinter

PadPrinter

Smallest outlines and letters are collected from a steel cliche and conveyed by a soft silicone rubber head (tampon) to the spectacle frame parts (metal or plastic) and plastic lenses.

Download Info-PDF ContactTorque control for welding and soldering points

Digital Display with torque sensor

Measurement range: +/- 200 Ncm with integrated overload protection

Accuracy level: +/- 0,2%

Drive: 1/4" HEX Socket

High-frequency generator

for preheating of plastic front parts.

A powerful High-Frequency "Tube-type" Generator for the preheating of plastic front parts made of Acetate.

Technical data:

| Electrical connection: | 400 V (+/- 10%) - 50/60 Hz |

| Working pressure: | 5 bar |

| Power: | 3,6 kvA |

| Frequency: | 28 to 30 MHz |

| Machine width: | 500 mm |

| Machine height: | 1220 mm |

| Machine depth: | 500 mm |

| Weight: | 85 kg |

"CE"-regulations are met

All data subject to change!

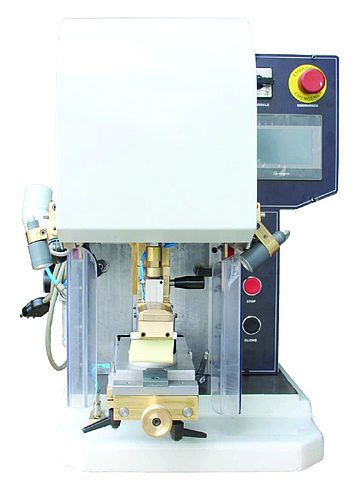

Double Station Front Bending Press

Automatic double Bending Press for Acetate Fronts

- Touch screen 5,6" commands

- Intangible safety barriers

- Soleniod valve for cooling air flow

Optional:

- Silicone based changable and regolable equipment on micrometric movement support

- Aluminum regolable basement

- Exchangable silicone set of dies.

COOLING MACHINE

These systems are designed to chill acetate components after base curving. As a result, they replace traditional cooling processes, which involve submersion in water.

There is a selection of 3 models:

Cooling machine with revolving plate

Cooling machine with single belt

Cooling machine with double belt

All models feature workpiece introduction via the front door. Parts are then thermically chilled following an automated process.

Revolving plate: this model allows for the workpiece (previously chilled on a sensor-controlled revolving plate) to be easily unloaded by hand via the front door.

Belt systems: instead of a revolving plate, workpieces are carried along one or two (double belt system) belts, resulting in a more even cooling process.

+ Efficiency

- parts do not need to be dried, saving one step over traditional processes

(drying of workpieces after cooling by submersion in water)

+ Consistent quality

- Controllable, automatic cooling process, thanks to adjustable temperature

and sensor-controlled conveyor systems

- Cooling by low-humidity air

Hydrodynamic Separator

This machine has been designed to save time normally required to separate tumbled pieces from abrasive elements of any type, shape and size.

Separation automatically is done within 3 minutes.

- Abrasives are conveyed to an appropriate container.

- All tumbled pieces are collected in a special extractable basket.

The machine eliminates the time normally spent to manually separate such pieces and can be used for ceramics and objects of any shape.

MACHINE DESCRIPTION

The machine is essentially made up of a frame-structure, to which the following elements are associated:

- A separation chamber positioned between an inlet collector and an outlet collector for treatment liquid.

- An input hopper communicating with the separation chamber for distribution of the elements to be treated.

- A pump to convey water to the separation chamber.

- A filtering bin to hold back abrasive elements suspended in the treatment liquid.

- A filtering bin to hold back separated elements.

Technical Data:

| Power supply: | 230 V 50/60 cycles |

| Cycle time: | 3 min. |

| Machine width: | 1500 mm |

| Machine height: | 1700 mm |

| Machine depth: | 600 mm |

| Weight net: | 150 kg |

"CE"-regulations are met

Download Info-PDF Contact