Power Cube Family

The Power Cube family is based on modular devices that are compact in size and that are technologically highly advanced. The devices in their various combinations, make up workstations that vary in complexity from a single manual soldering point to multiple automatic points in which operator intervention is limited to the loading of the pieces to be processed.

Download Info-PDF More

CEIA Power Cube

CEIA the Power Cube family stands for unlimited induction soldering technology and meets all challenges of modern spectacle frame manufacturing. The POWER CUBE generators are available in different power sizes and can be completed by control unit MASTER CONTROLLER V3+ with various options for automated processing. The POWER CUBE FAMILY is manufactured to ISO standards and features supermodern microprocessor technology, carefully respecting all current safety regulations.

Extensive literature with all technical details is available upon request.

Master Controller V3+

Electronic control unit with infrared temperature control

ADVANCED version can additionally connected to/with:

- Power Cube HF-Generators

- Gas dispensers to avoid oxydation

- CEIA solder-wire feeder, feed speed and amount of wire adjustable

Temperature range:

Compact Direct Sensor SH15/SLE 550 D4 500-2000°C

System 900

CEIA high frequency generators 3,5 KW

with integrated temperature control and antioxidizing gas system

Semiautomatic workstation with small space requirement due to combination of Power Cube 45 and advantage of Master Controller Basic in one compact system

SG-10

Accessories for protective atmosphere for cooling the workpiece and to prevent from oxidation including:

- gas pipes

- stands

- valves

- gas flow regulators

Only in combination with Master Controller V3+ BASIC or ADVANCED version.

LG-100

Automatic solder wire feeder

Parameters like the piston movement, the alloy feed speed, the quantity of the wire and the torque of the motor can be set at the control unit

Only in combination with Master Controller V3+ ADVANCED (including option wire feeder).

Pyrometer

Compact Direct Measuring sensor with LED aiming light

for Master Controller V3+ BASIC

and Master Controller V3+ ADVANCED

Including stand, for precise control of the temperature of the workpiece by means of an optical pyrometer.

Temperature range:

Compact Direct Sensor SH15/SLE 550 D3 200-1600°C

Compact Direct Sensor SH15/SLE 550 D4 500-2000°C

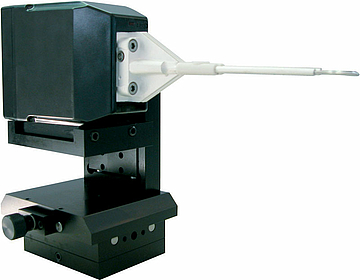

HH-10

Standard Heating Head HH-10 including foot pedal, excl. inductor holder.

Illustrations shows Heating Head HH-10 - with inductor holder* - mounted on precision support ES-35*

*(not included)

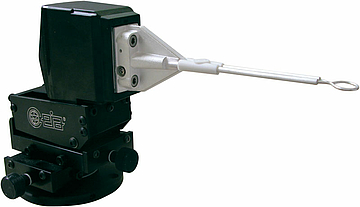

HH-15

Miniaturized Heating Head HH-15 including foot pedal, excl. inductor holder.

Illustrations shows Heating Head HH-15 - with inductor holder* - mounted on adjustable support ES-25*

*(not included)

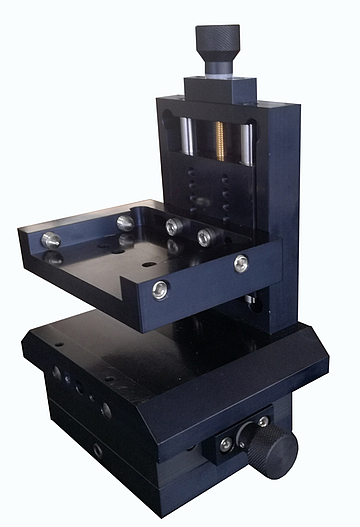

Adjustable precision support ES-35

High precision support for the heating head

The positioner is produced to facilitate positioning on symetrical workstations, even at very close distances.

It allows a micrometric movement of the head along the horizontal axes and the vertical axis and a rotation of 360°.

The dimensions of the support without the head are: 135x140x195mm (LxWxH).

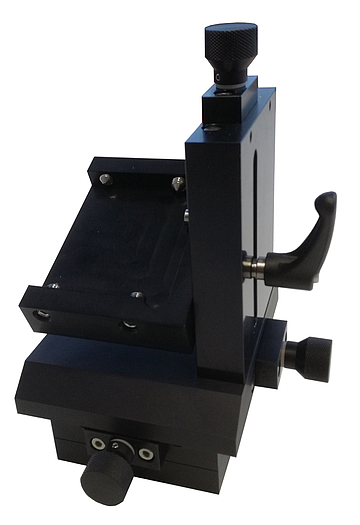

Adjustable precision support ES-35-T

High precision support tiltable for the heating head

The positioner is produced to facilitate positioning on symetrical workstations, even at very close distances.

It allows a micrometric movement of the head along the horizontal axes and the vertical axis and a rotation of 360°.

Additionally it is equipped with a handle for quick-adjustment.

The dimensions of the support without the head are: 135x140x195mm (LxWxH).

Adjustable precision base ES-3M

For optical Pyrometer and wire feeder

A special adjustable precision base may be mounted under the support of the optical pyrometer or under the support of the solder-wire feeder.

This accessory allows perfect aiming of the pyrometer in the soldering area, avoiding errors in temperature readings during a work cycle.In addition, the base is particularly useful since it allows improved positioning of the wire feeder, thereby providing optimum soldering, without dripping.The base is designed to be fastened to the workbench surface.

The positioner allows a micrometric movement of the support along the horizontal axes and vertical axis.

The dimensions of the positioner are: 130x140x115mm (LxWxH); length of the rod: 200mm

Soldering fixtures

HAUG provides suitable tooling for all soldering operations. All fixtures are designed and manufactured in cooperation with our technicians. Customers’ production flows and technical drawings of components form the basis of these custom made solutions.

Chiller

Further information on request

Torque control for welding and soldering points

Digital Display with torque sensor measurement range: +/- 200 Ncm

with integrated overload protection :

- Accuracy level: +/- 0,2%

- Drive: 1/4" HEX Socket