Schüssler S-615

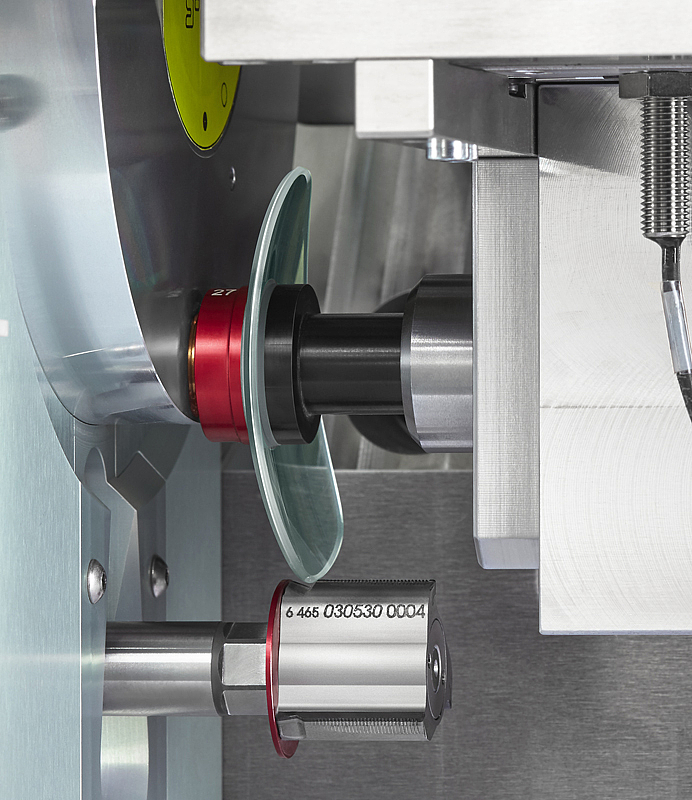

Fully-automatic CNC Milling Machine for plastic lenses

Particularly designed for the industrialized shape cutting and

bevelling of all common plastic materials with a production rate

of up to 1100 lenses per hour (depending on lens material and thickness)

Its compact size and proprietary interface make it an

easy to use reliable lens machinig centre.

Workpiece-dimensions:

- Lens blank diameter: max. Ø 80 mm or 80 x 90 mm

- Lens blank thickness: 0,5 to 3,0 mm

- Minimum size of finished lens: 20 mm

- Possible base curves: from 0 to 10, however depending on shape and profile of finished lens.

- Direct data import (DXF, F, C, G) via USB or network

Features:

- The machine comes with total 2 x USB and 1 x LAN connection for model data exchange via Ubiquity software (Industry 4.0). Router for remote maintenance included

- All commands are entered via graphic touchscreen and LAN connection

- The machine allows easy programming of the left respective right lens shape

- An alternating processing of left and right lenses is possible

- All common materials of plastic lenses up to a thickness of 3mm are possible to process

- The finished lens profile corresponds exactly to the lens bevel as edged by the optician

- Integrated safety function "Safe Torque Off" for the drives

- Bus-system EtherCAT

- Access of model data on a shared directory available as an option (BS-1-514-615)

- External chip extraction system required (Ø100mm)

- Working area and finished lenses are electrostatically discharged

- Machine does not permit wet processing!

- All original accessories available at F.W. Haug, e.g. loading magazines, unloading magazines, unloading belts and cutters

- Cutters can be returned for re-sharpening

- Comprehensive training either in Germany, or at customer site available upon request

| TECHNISCHE DATEN / TECHNICAL DATA | SCHÜSSLER S-615 |

| Netzanschluss / Power supply | Spannung / Voltage 230V AC 50/60Hz. Netzschwankungen / Mains fluctuations: max. +/- 10% Netzsicherungen / Fuses: 16 A Anschlusswert / Power Consumption 2 kW |

| Produktionsausstoß / productivity | Bis 1100 St./Std (Werkstoff- und Dickenabhängig) Up to 1100 pieces/h (depending on material and thickness) |

| Basiskurven / base curves | 4 - 10 (abhängig von Rohglasgröße) 4 – 10 (depending on the size of lens blanks) 0 - 4 möglich (Option) / 0 - 4 possible (optional) |

| Datenanschluss / Data connections | USB (2x), LAN (1x) |

| Programmierung / Pogramming | Übergabe von Daten durch USB oder LAN mittels Ubiquity / Data transfer (DXF, F, C, G) through USB or via LAN – Ubiquity software |

| Lärmeinstufung / Noise level | max 85 dB |

| Breite / width | 1150 mm (mit Monitor / with display) |

| Tiefe / depth | 730 mm |

| Höhe / height | 1590 mm (mit Monitor / with display) |

| Nettogewicht / net weight | 288 kg |

| Bruttogewicht / gross weight | ca. / approx. 470 kg |

| Maße Kiste / measurements wooden box | 1530 x 980 x 1660 mm |

| Platzbedarf / Space requirement | ca. / approx. 3,0 m² |